Sales, Maintenance & Development of Turbo-Molecular Pump and Controller

PROfessional SOLution to service you

Brand of service

Filter Categories

All

Turbo-Molecular Pump

Controller

-

anemptytextlline

anemptytextlline -

anemptytextlline

anemptytextlline -

anemptytextlline

anemptytextlline -

anemptytextlline

anemptytextlline -

anemptytextlline

anemptytextlline -

anemptytextlline

anemptytextlline -

anemptytextlline

anemptytextlline -

anemptytextlline

anemptytextlline -

anemptytextlline

anemptytextlline -

anemptytextlline

anemptytextlline -

anemptytextlline

anemptytextlline -

anemptytextlline

anemptytextlline -

anemptytextlline

anemptytextlline -

anemptytextlline

anemptytextlline -

anemptytextlline

anemptytextlline -

anemptytextlline

anemptytextlline -

anemptytextlline

anemptytextlline -

anemptytextlline

anemptytextlline -

anemptytextlline

anemptytextlline -

anemptytextlline

anemptytextlline

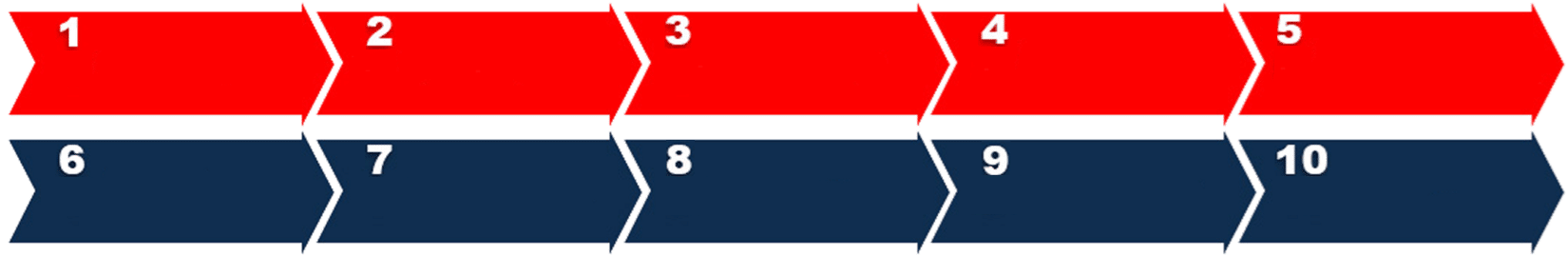

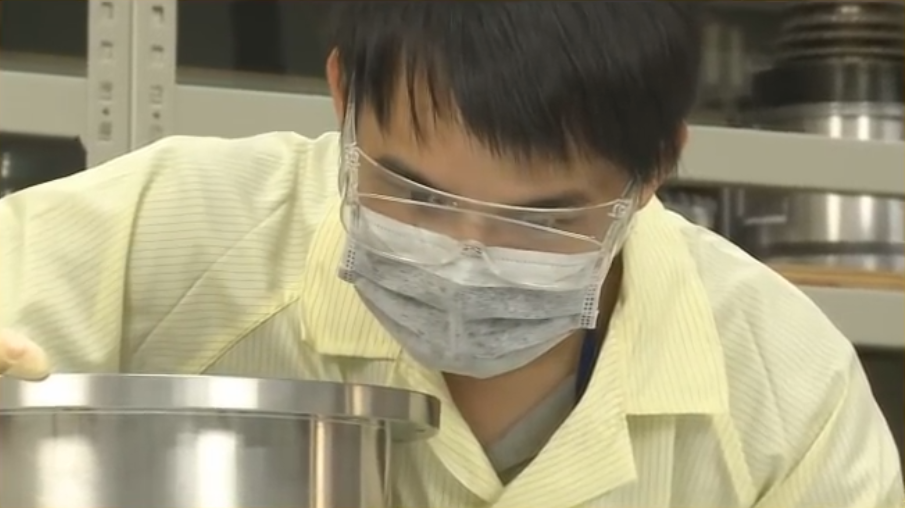

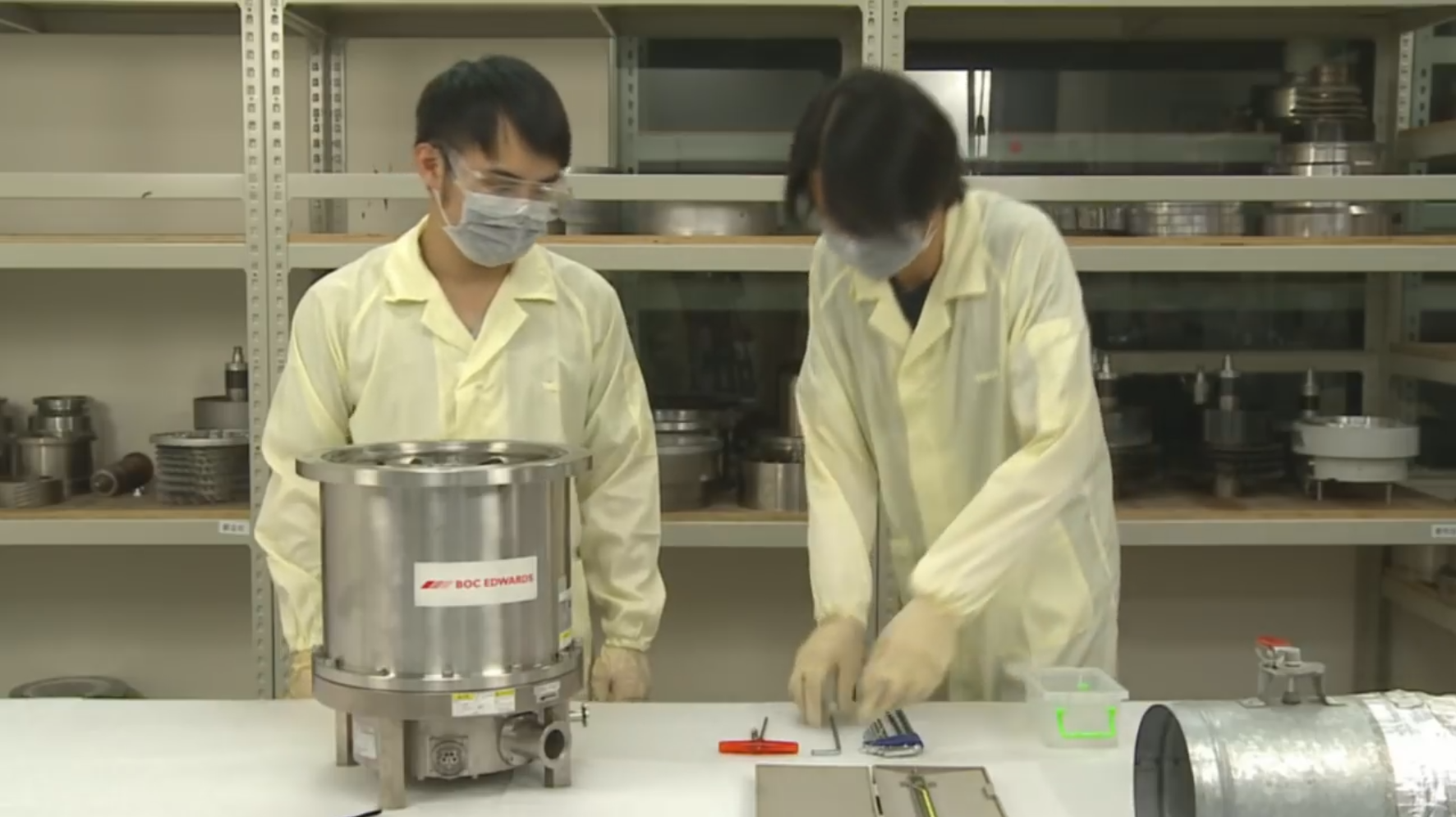

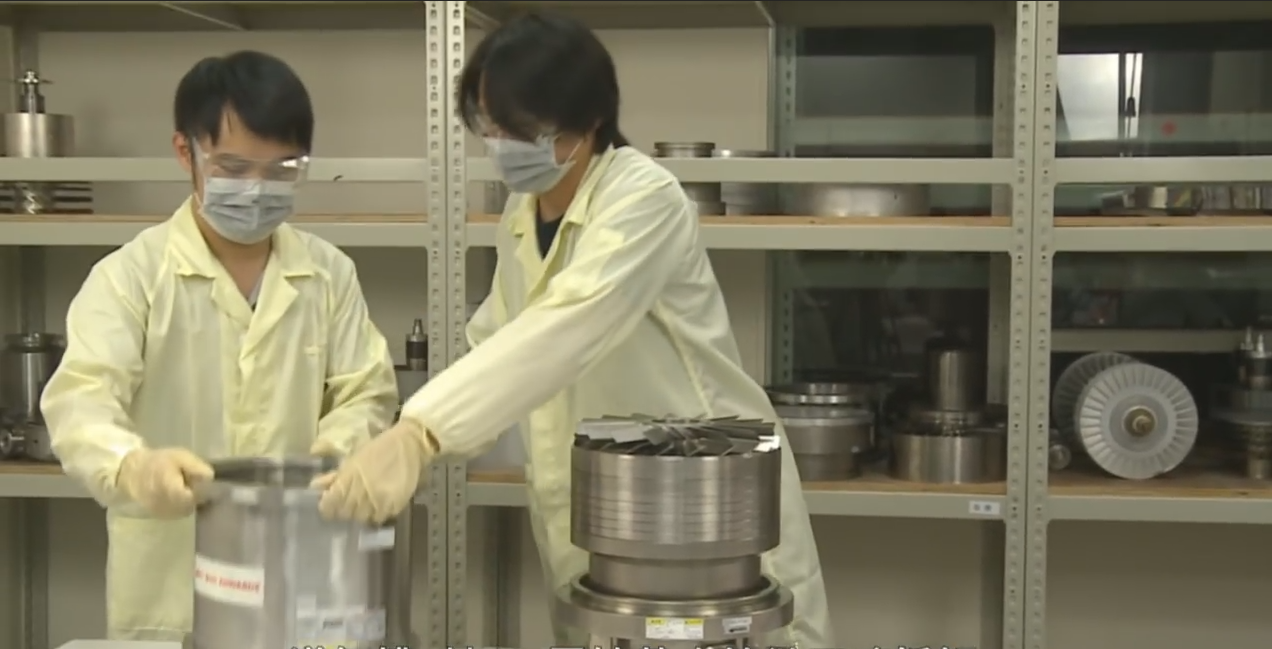

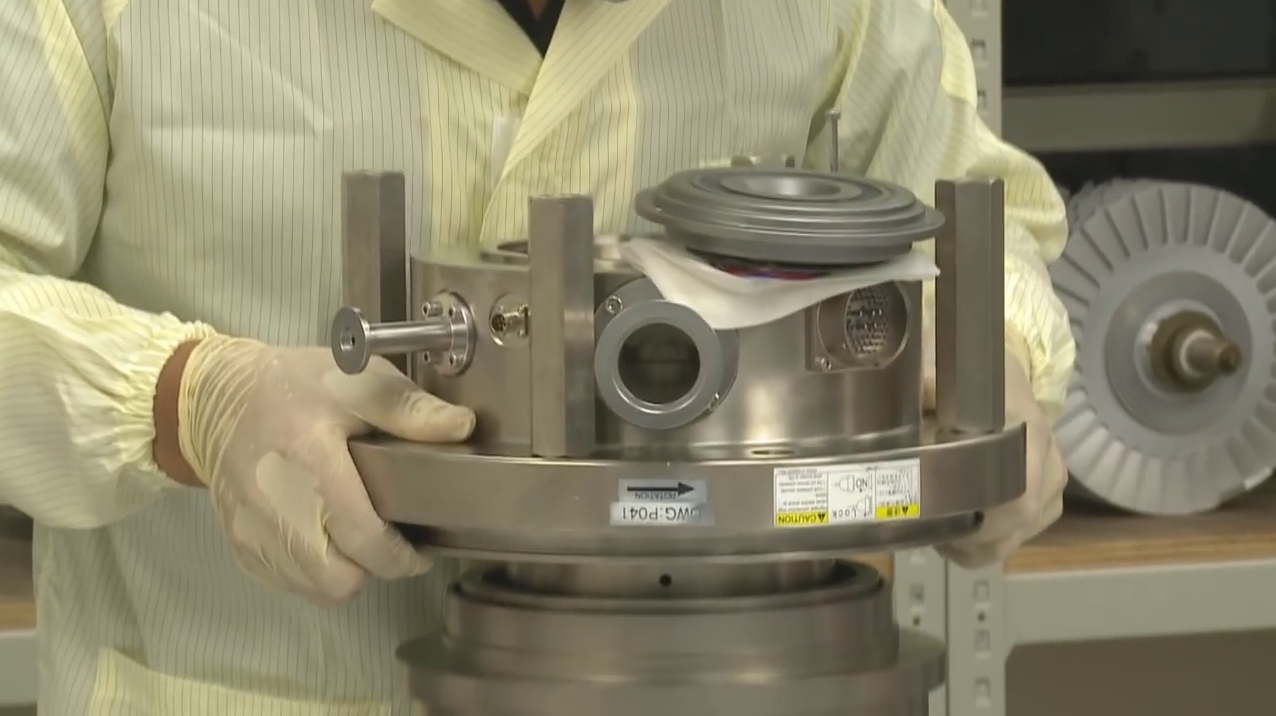

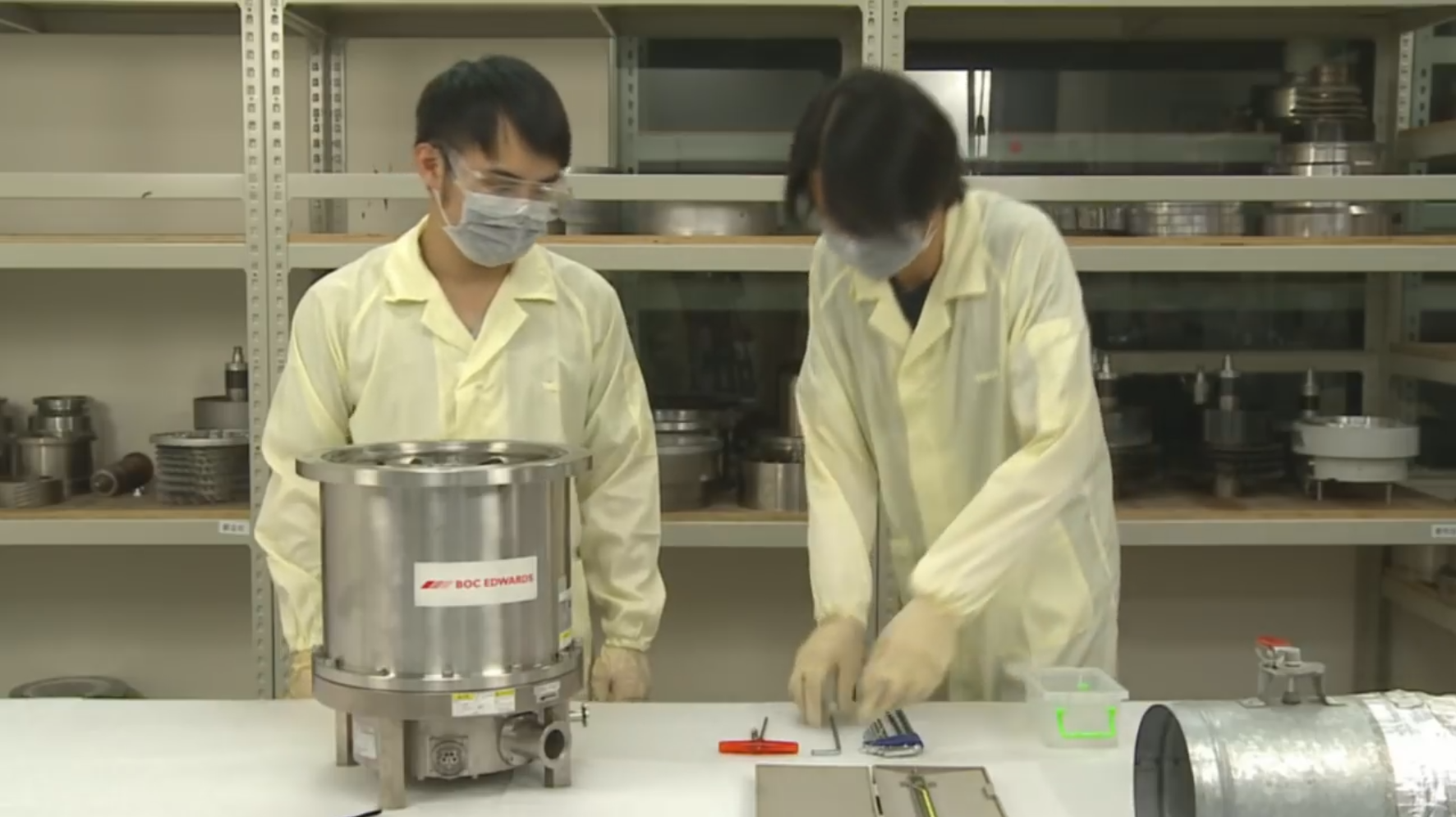

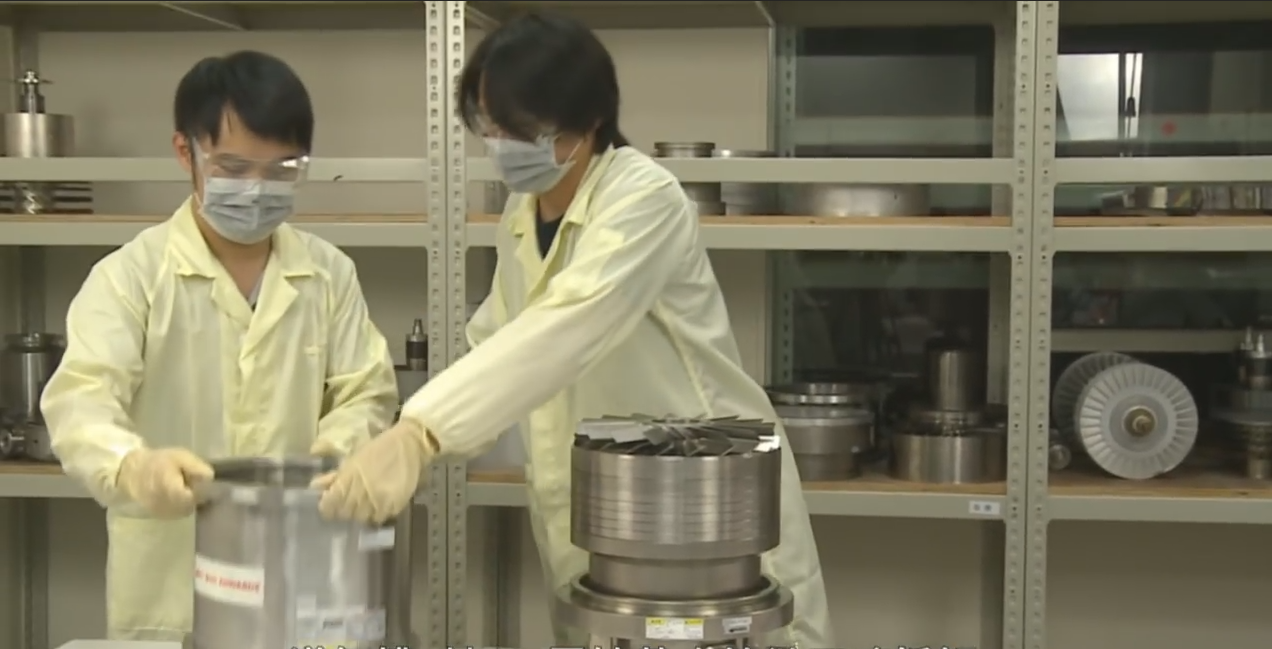

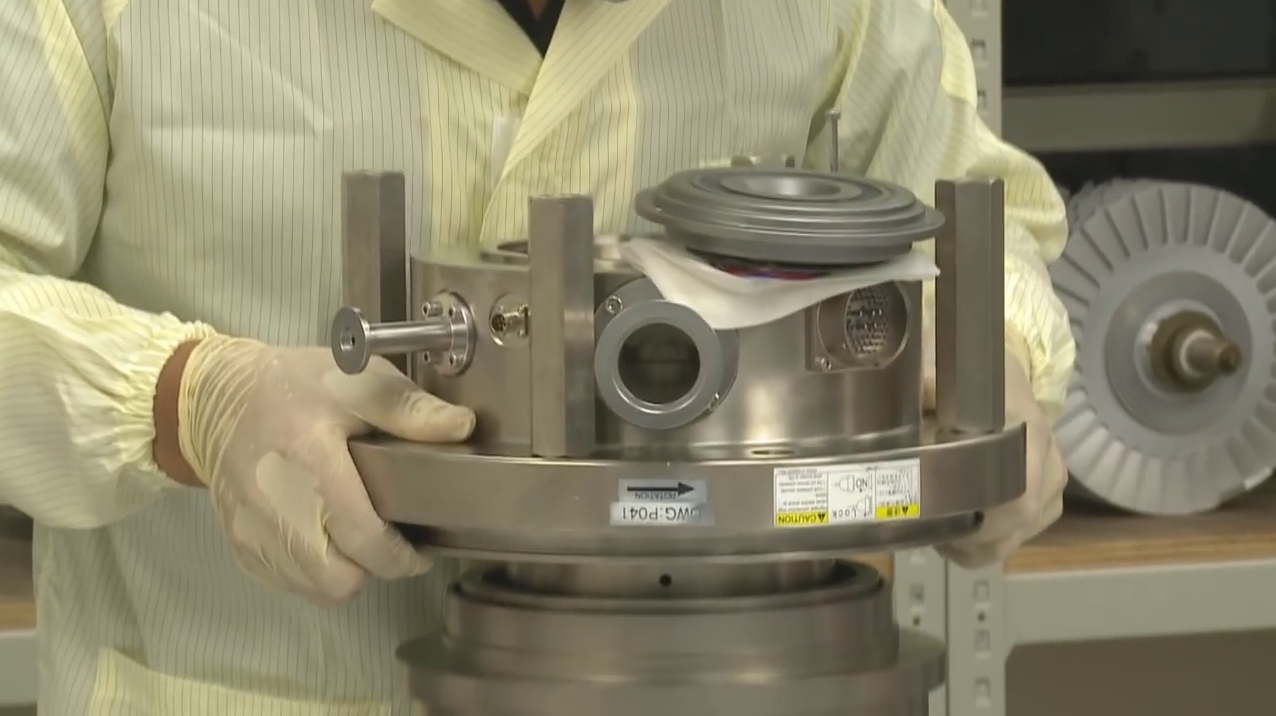

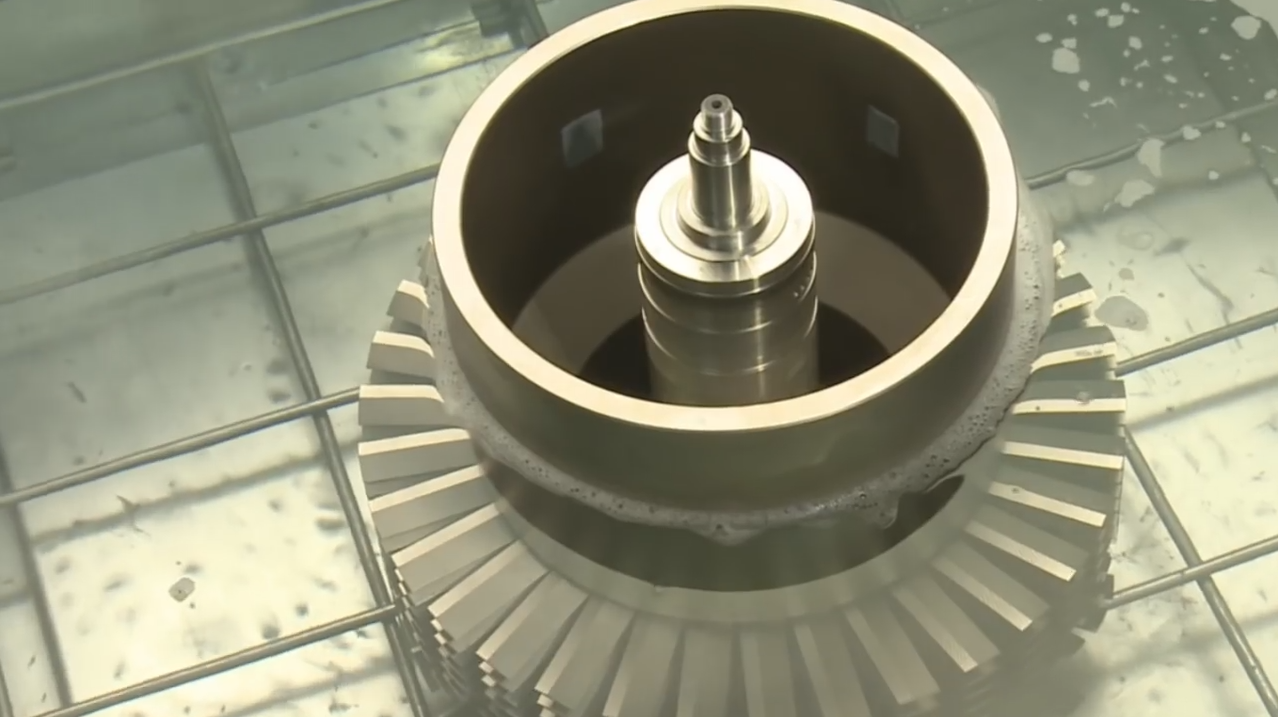

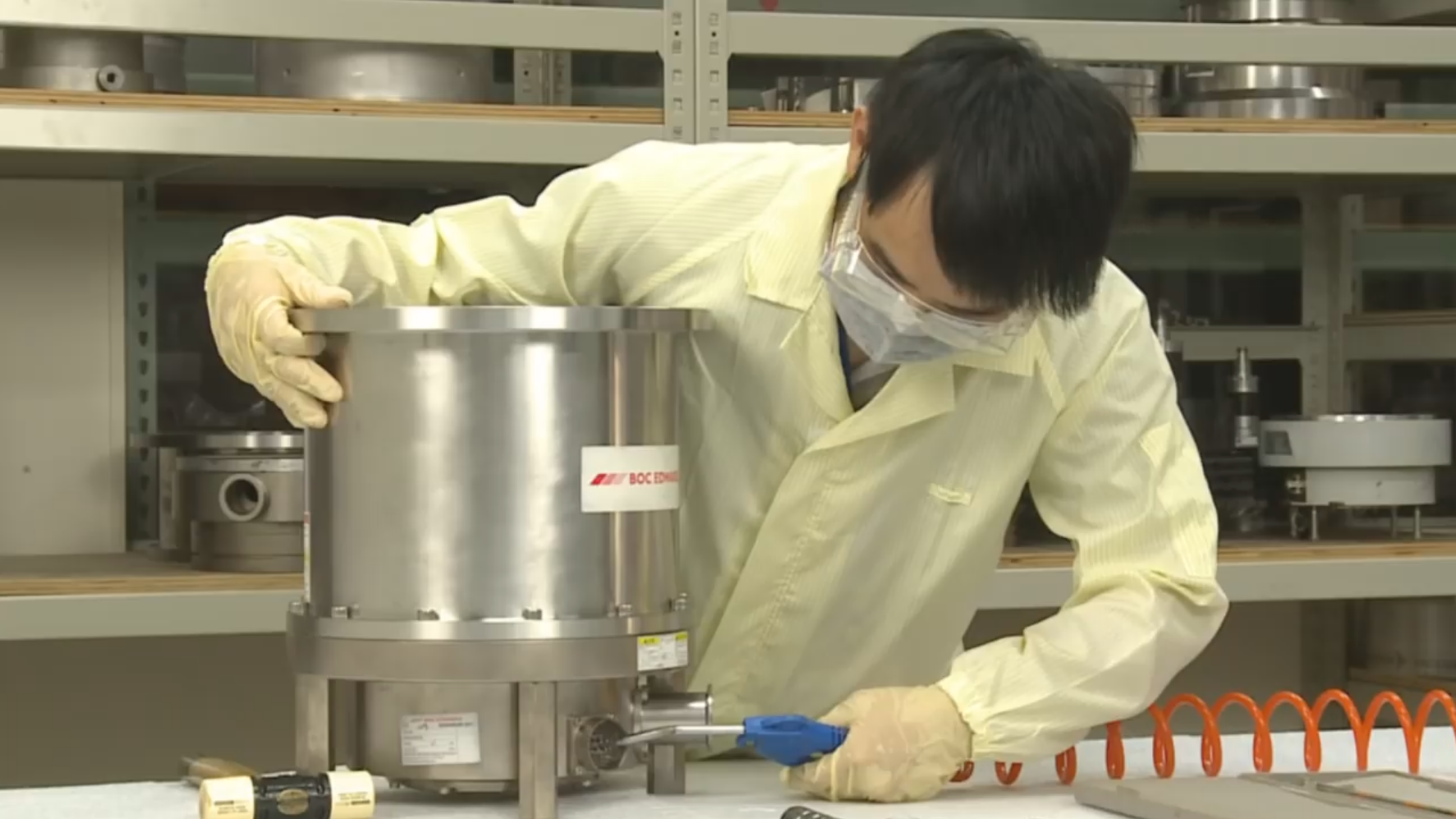

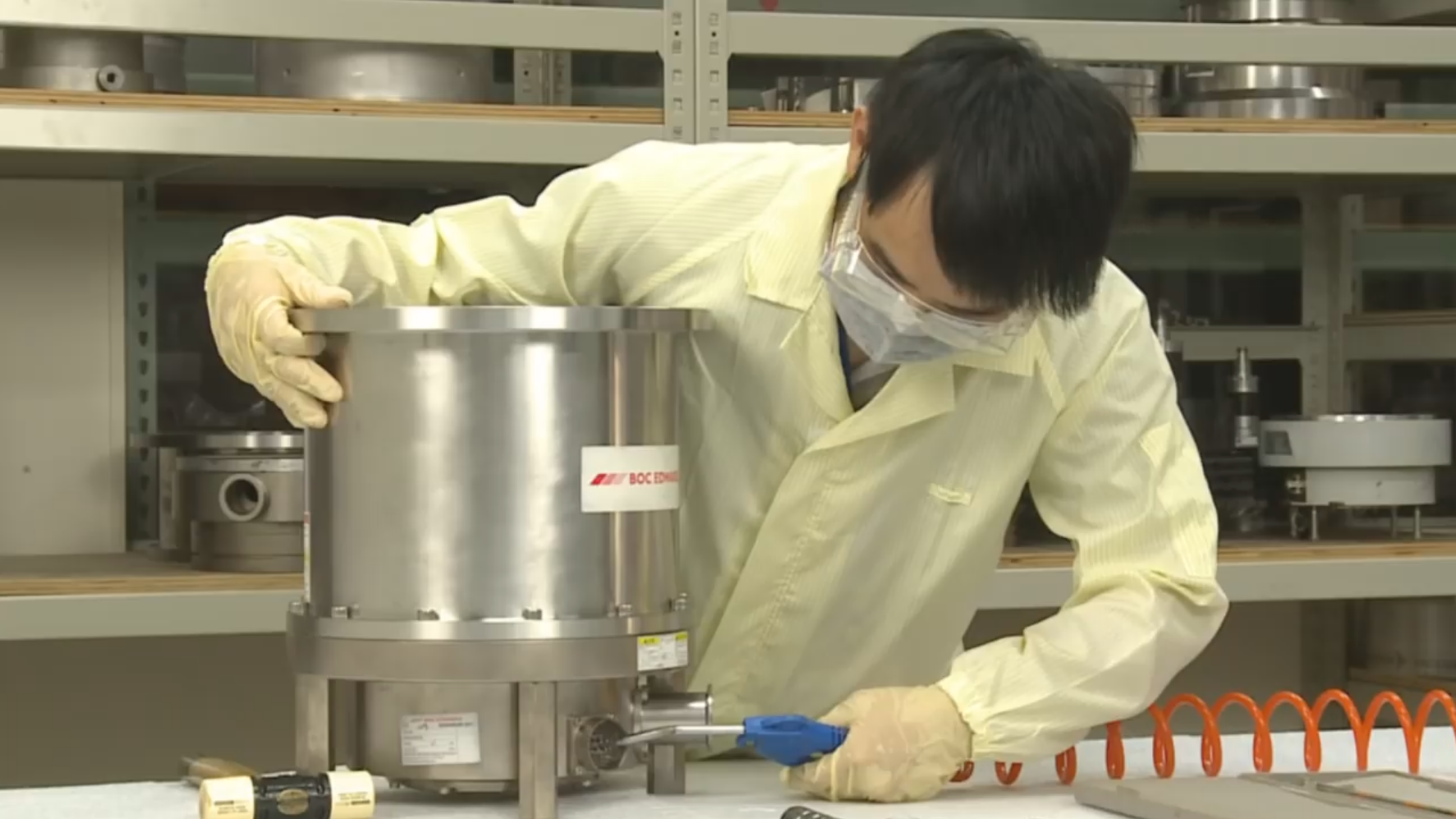

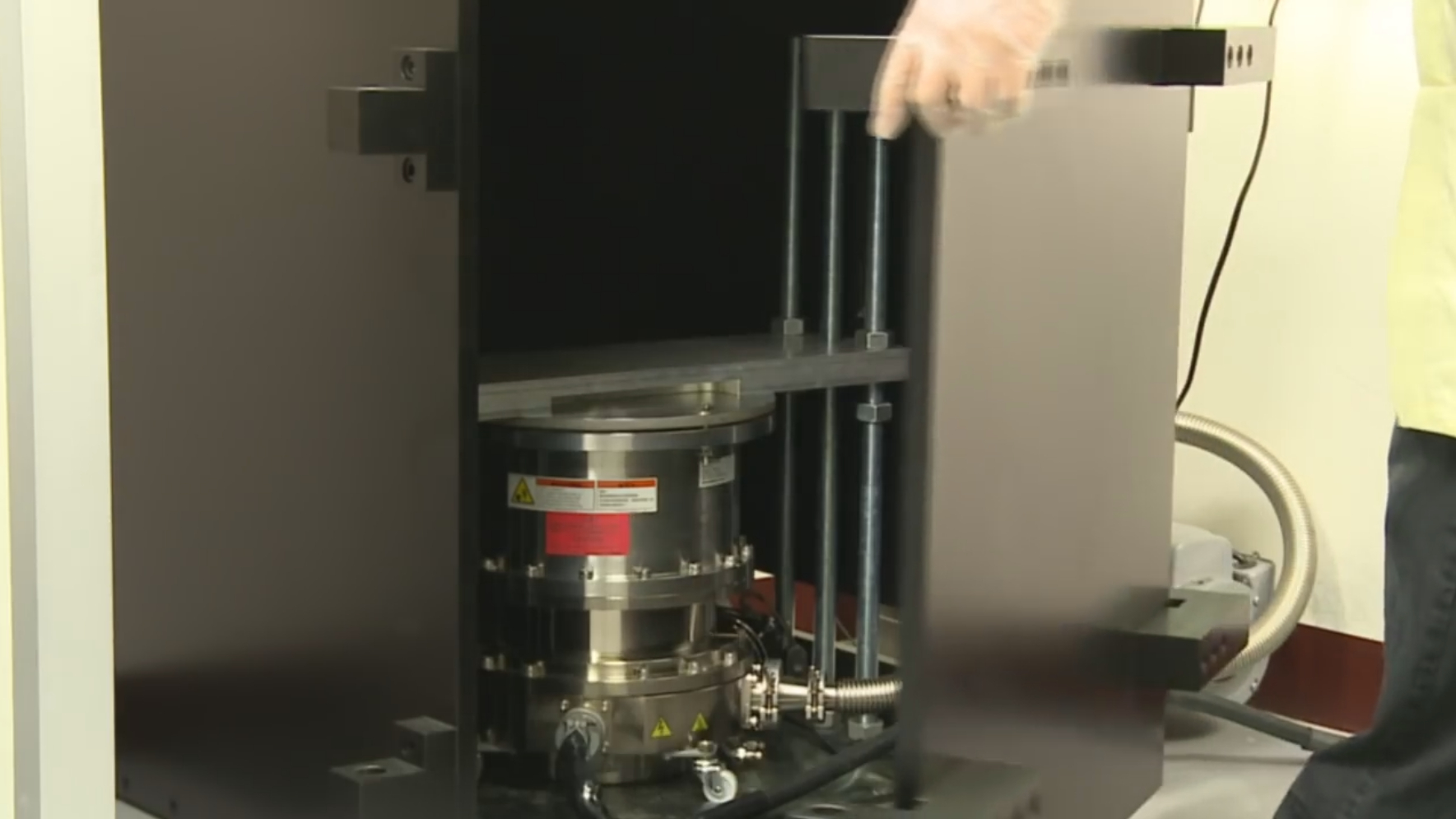

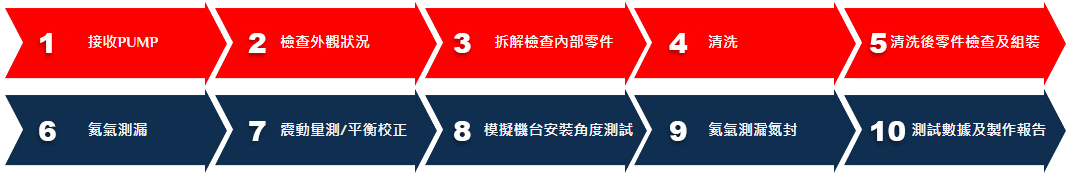

Maintenance process

Receiving Pump

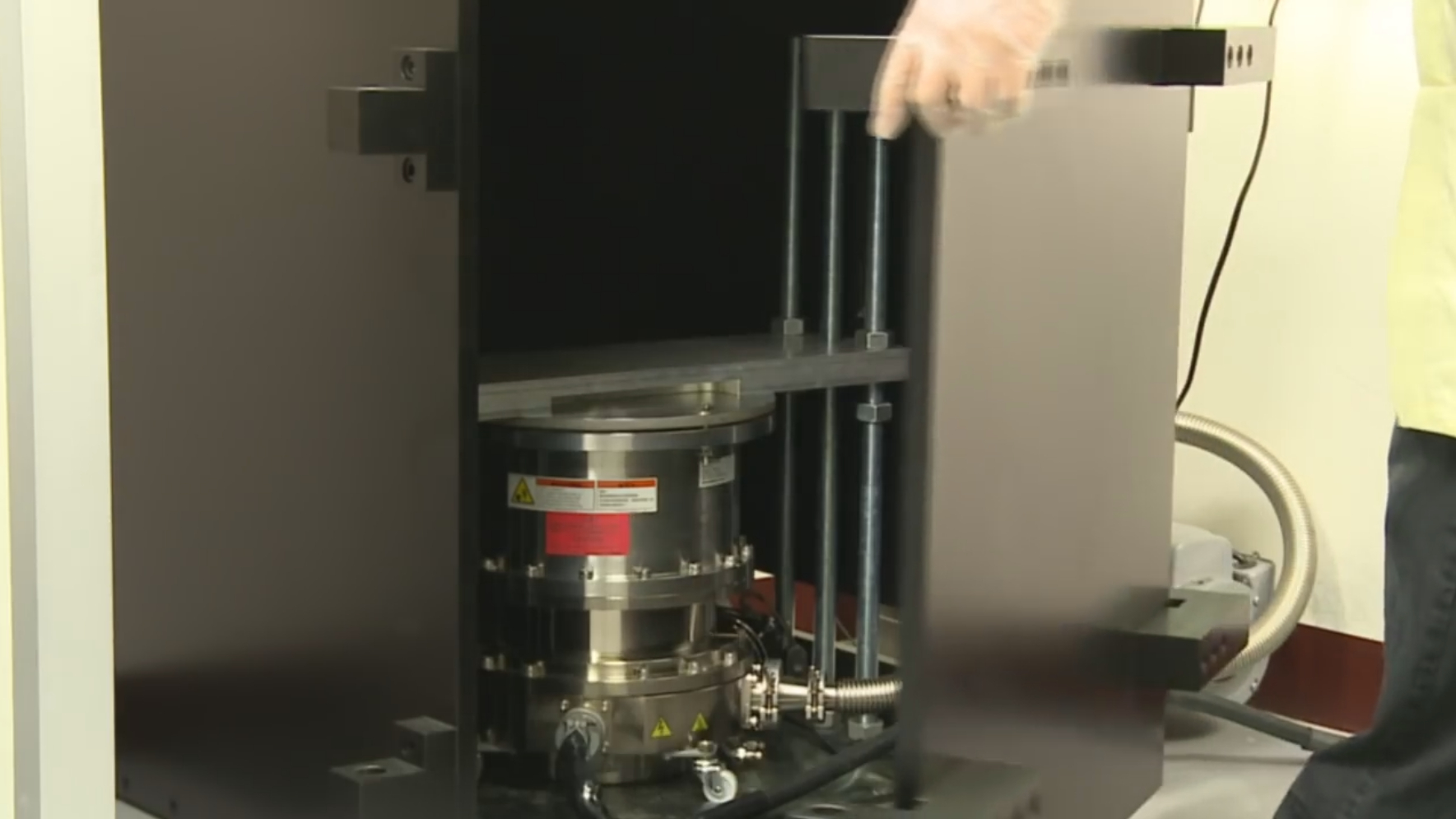

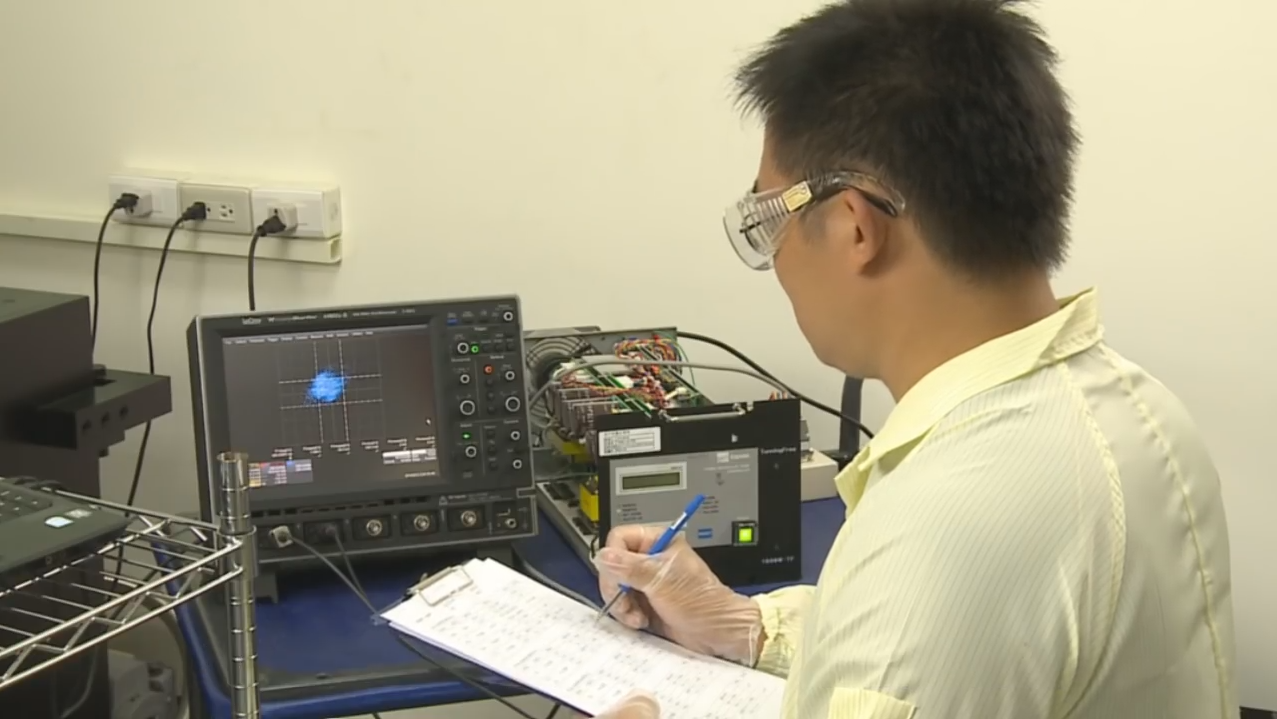

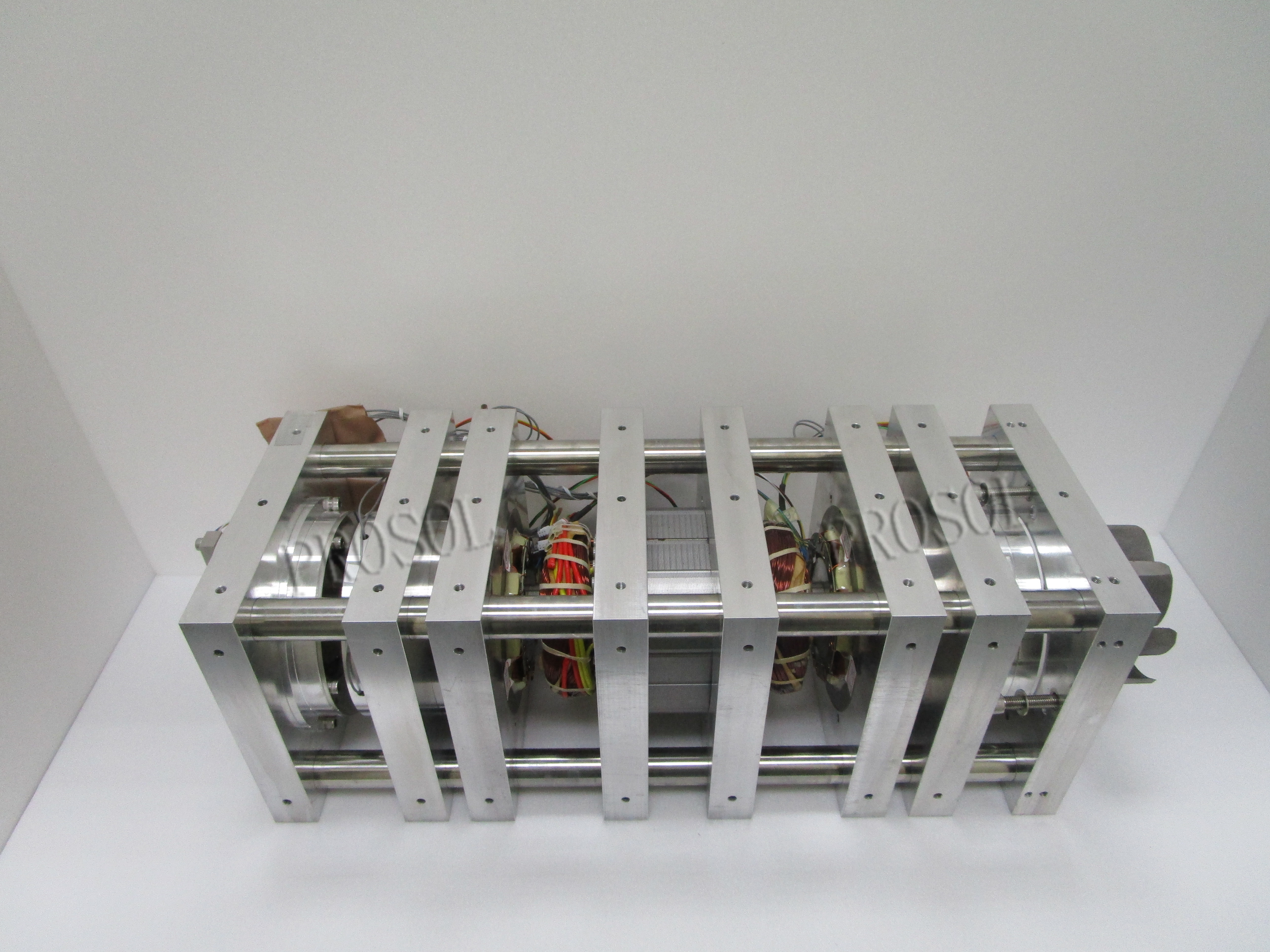

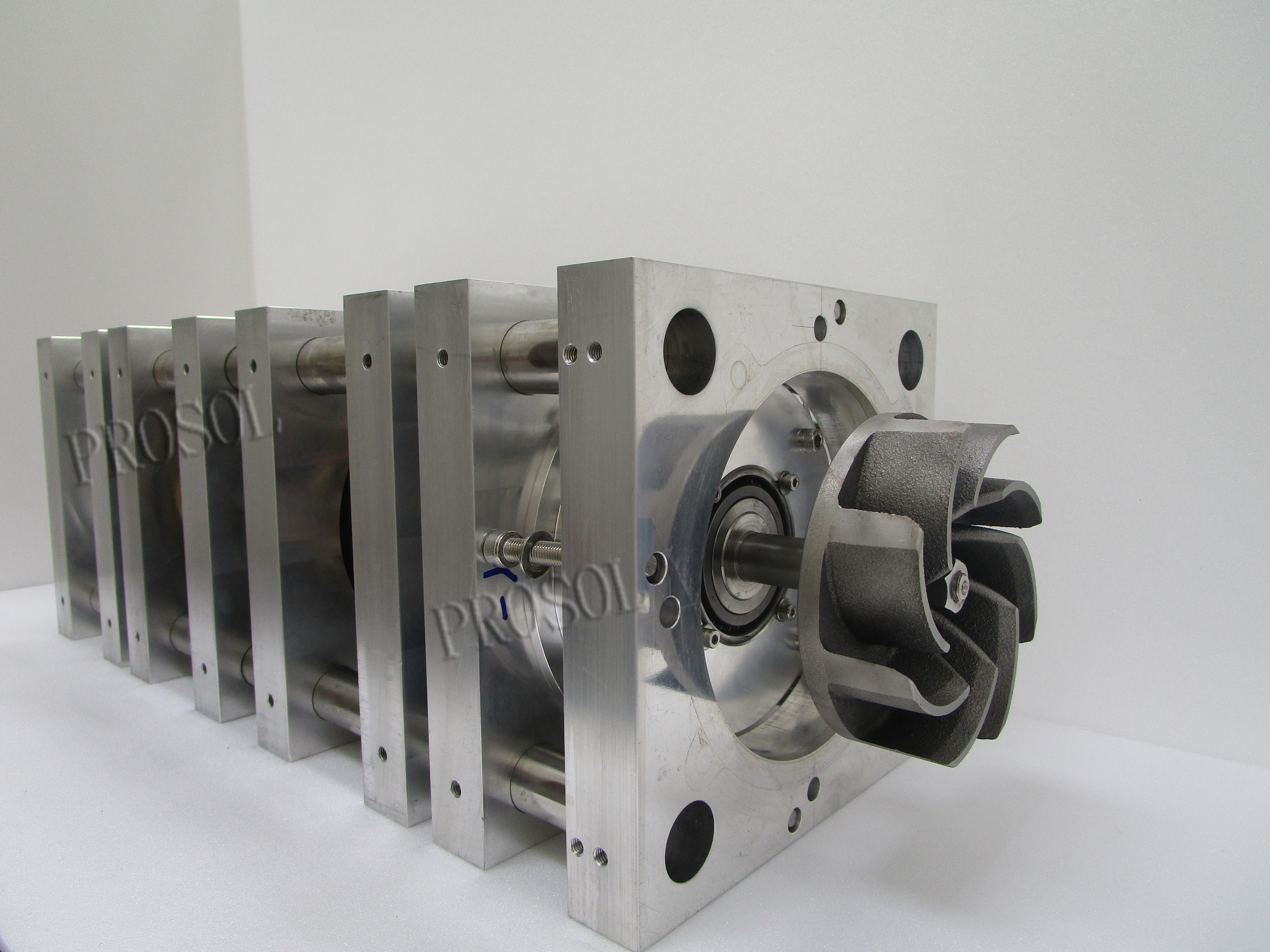

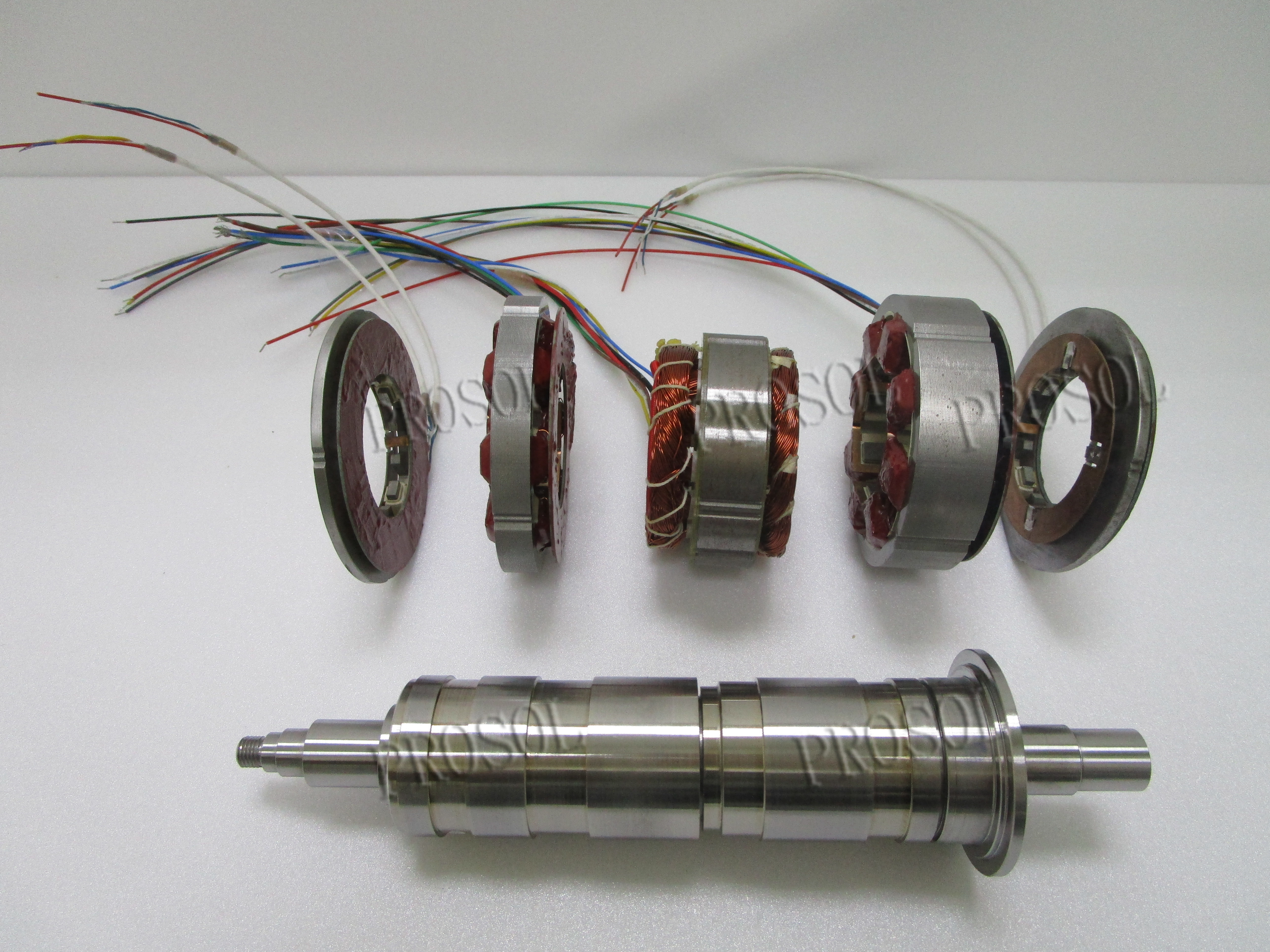

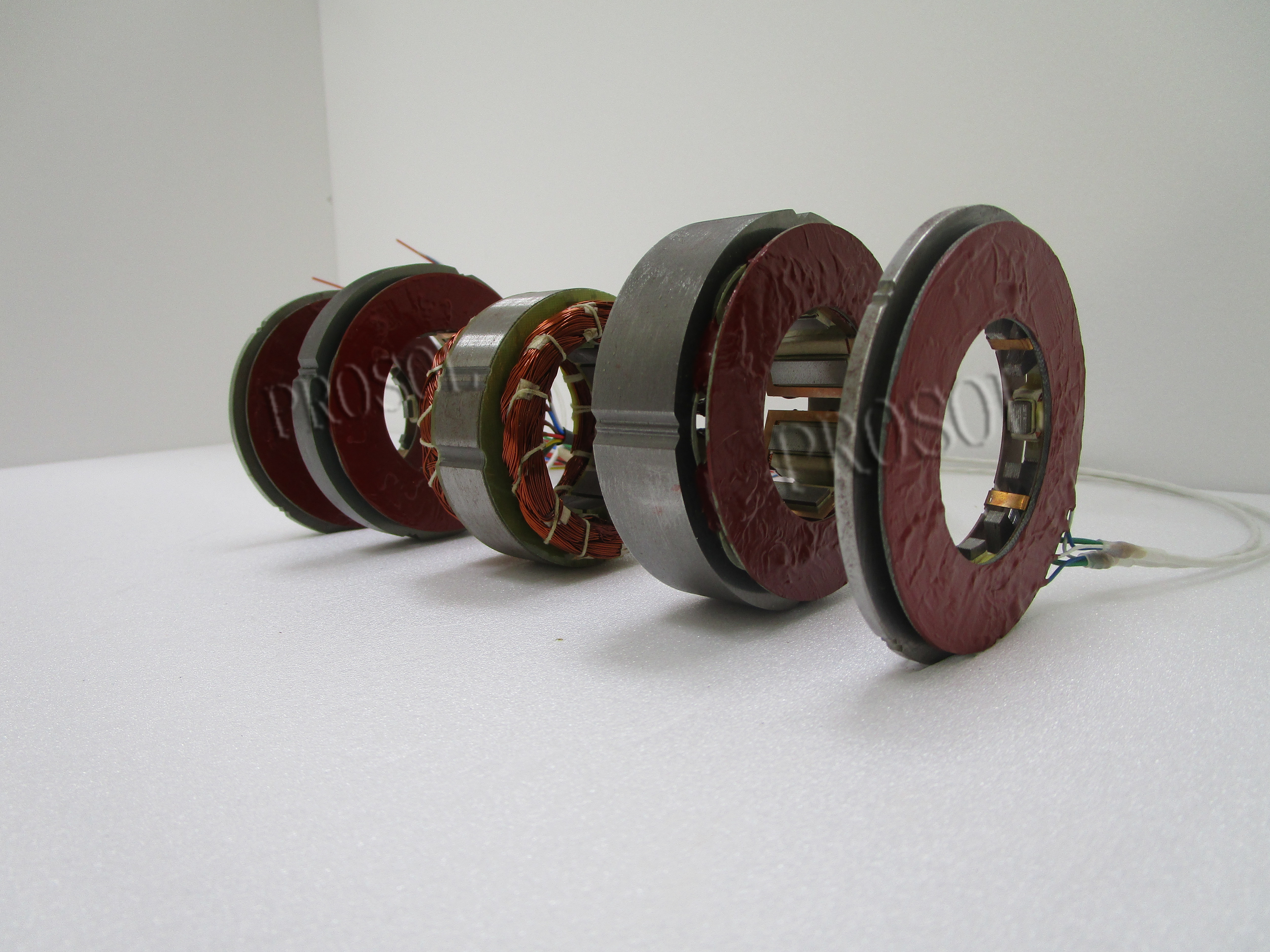

Maglev System Development

PROfessional SOLution to service you

Providing customers with a total solution for high-speed maglev rotor systems, customizing magnetic floating bearings according to customer requirements, from design to production in Taiwan. Through the advanced magnetic bearing control system on-line tuning software, optimize the controller parameter design to provide customers with high performance, high reliability of the magnetic bearing components and control technology.

Potential Magnetic Float System Application

Magflev Compressor for Cold Water Maker

Potential Magnetic Float System Application

Maglev Liquid Science Pump

Magnetic Flywheel Power Generation

Maglev Elevator

Maglev Machining Spindle

Maglev Deceleration System

…………….

Magflev Compressor for Cold Water Maker

under construction

Previous

Next

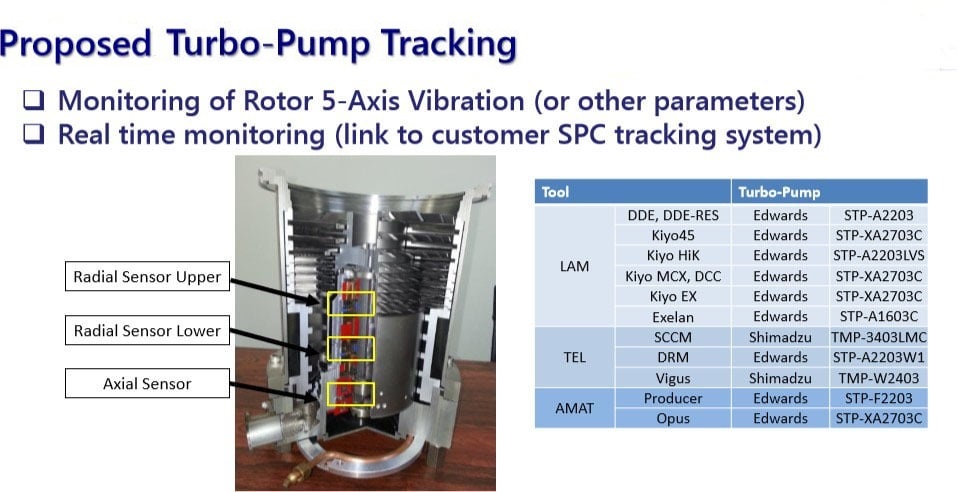

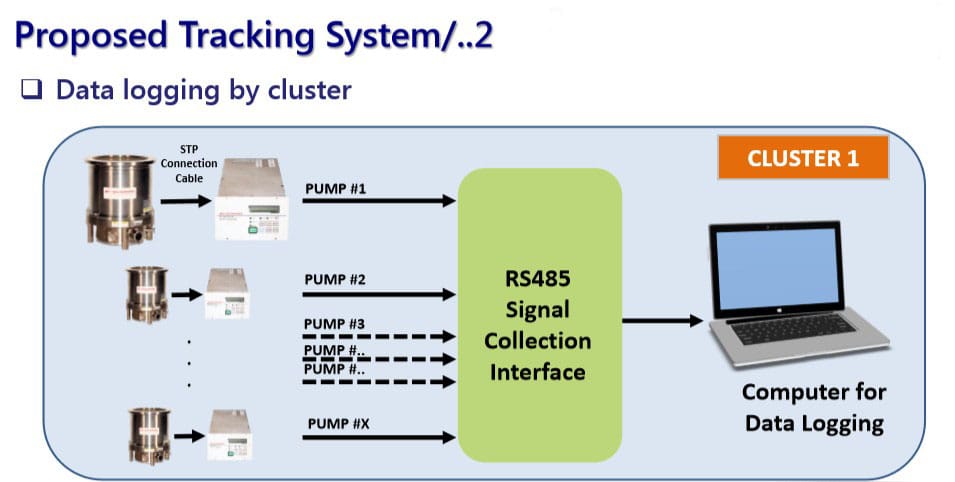

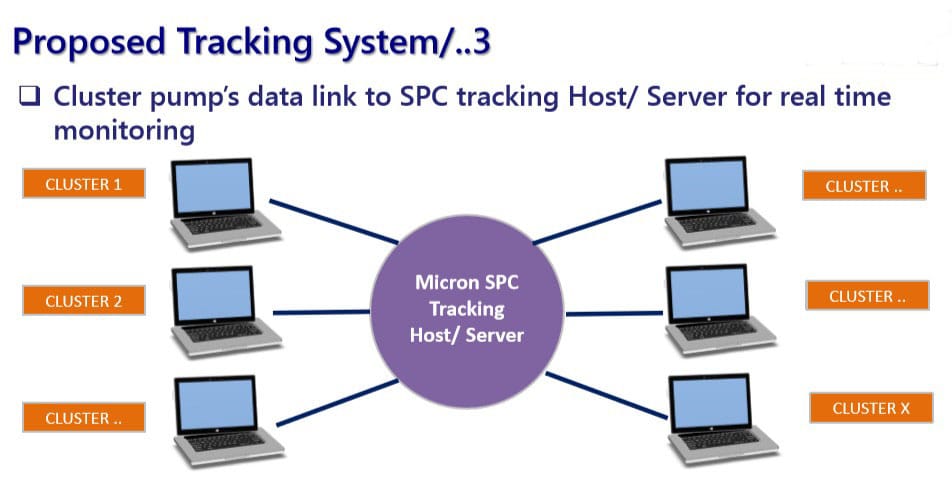

Digital Monitoring System

PROfessional SOLution to service you

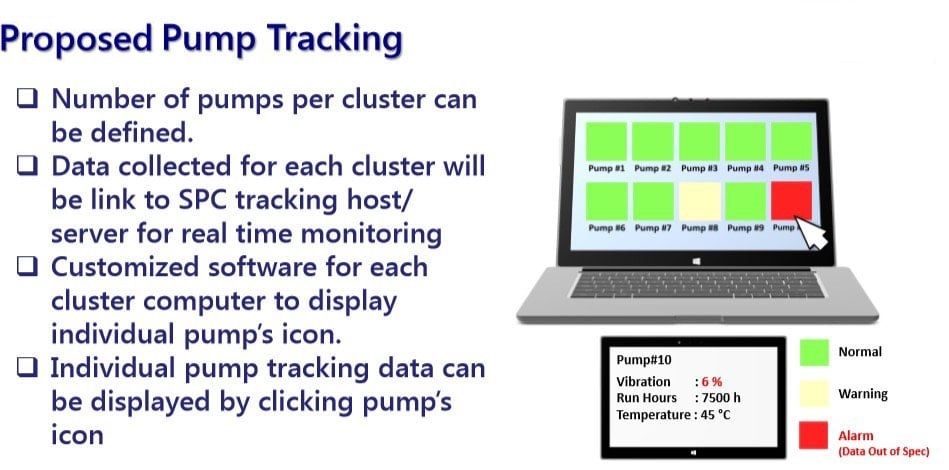

Architectural Planning

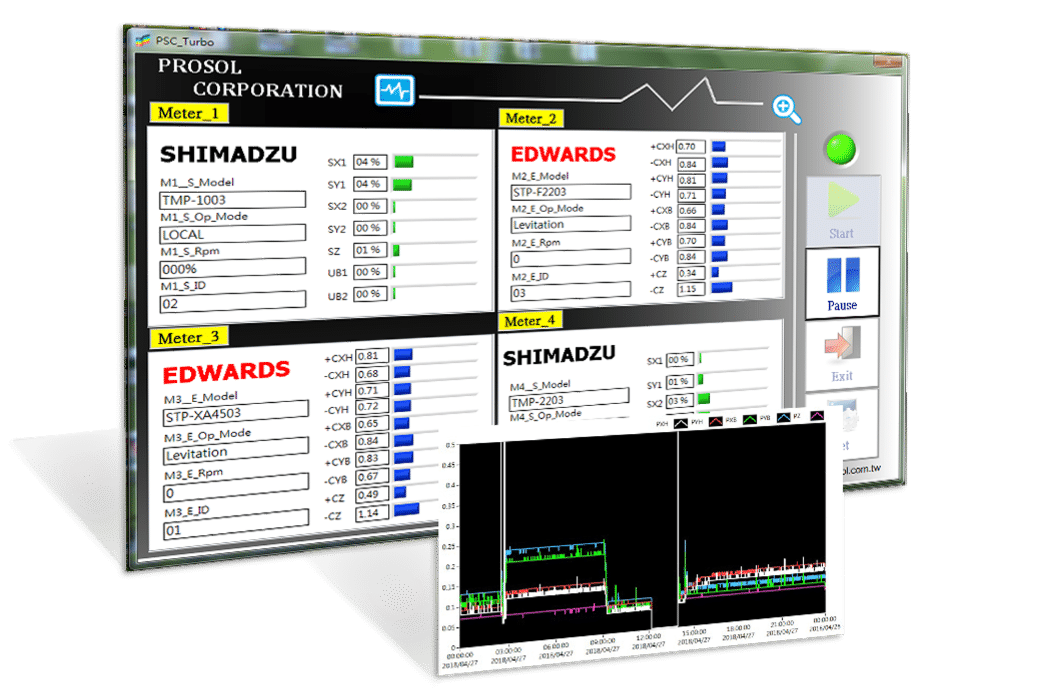

Software Test Screen

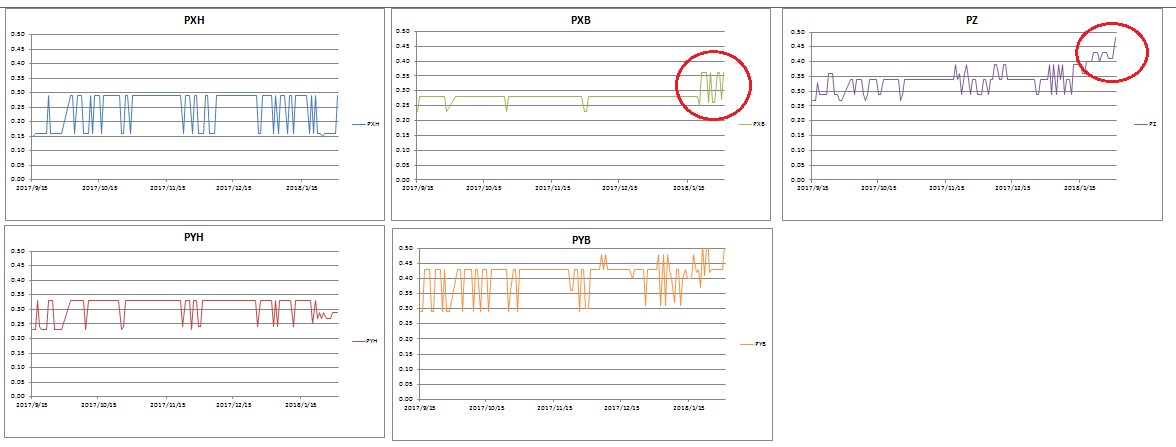

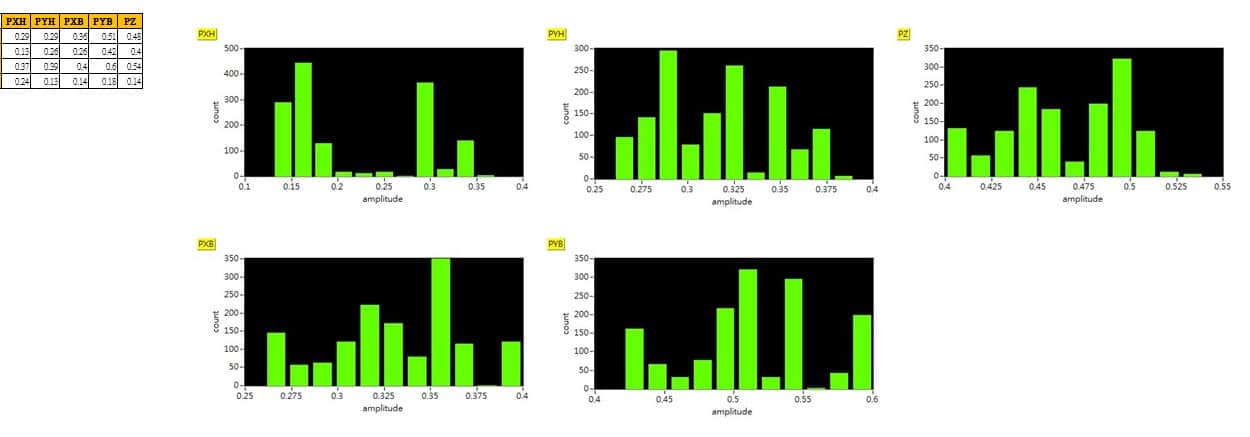

Anaylsis of Machine Condition

Live Example

Architectural Planning

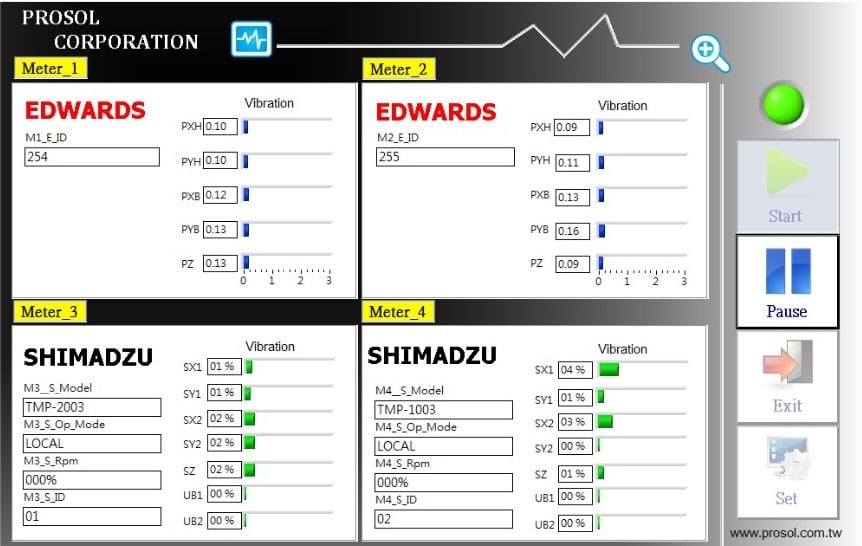

Software Test Screen

Multi-Machine Integration (Edwards + Shimadzu)

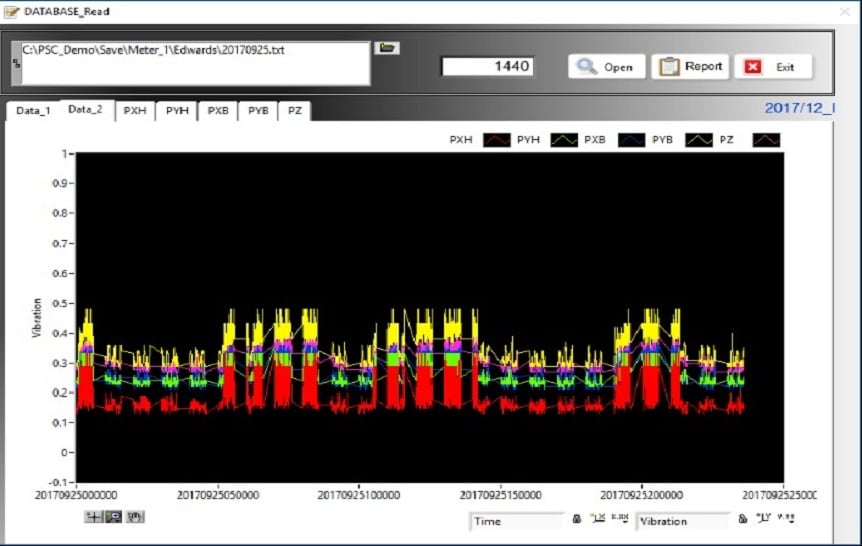

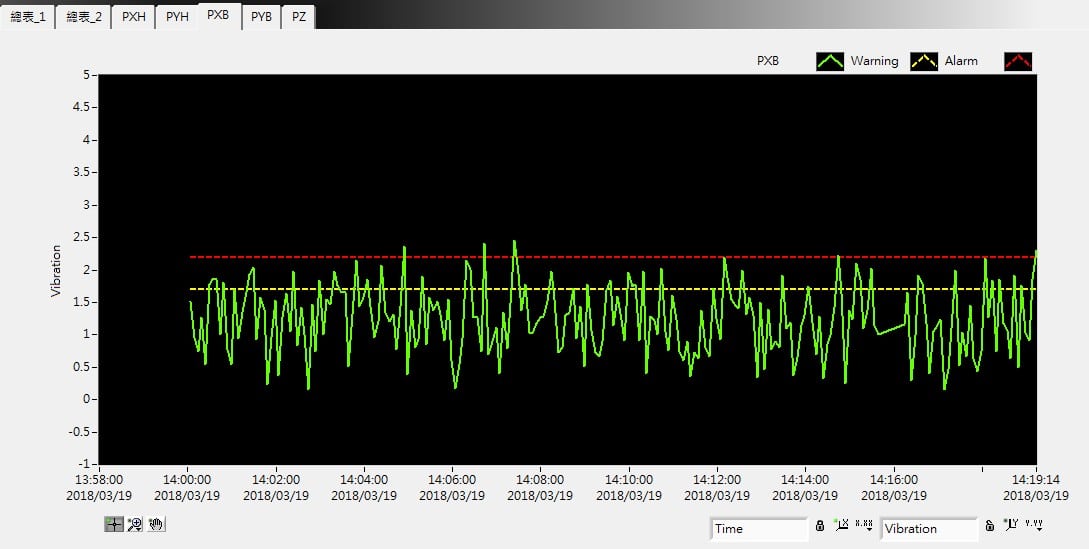

Anaylsis of Machine Condition

Live Example

=>

=>

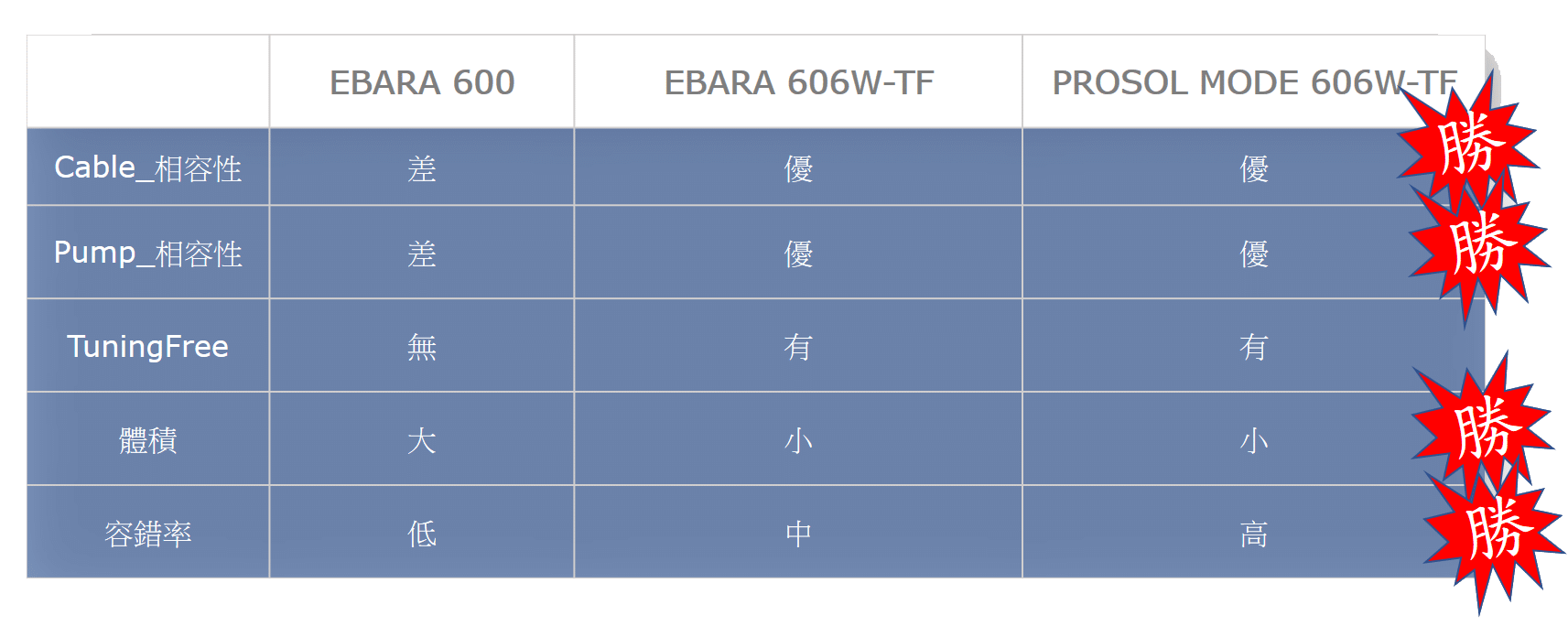

Advantage:

- The original ET-600 hardware can be upgraded without any changes, and the risk of changing the machine can be reduced.

- The 606W-TF TuningFree feature is ported to the ET-600 Upgrade version to increase the cable length/pump pairing fault tolerance.

- Prosol technology is self-contained and there is no need to worry about missing materials and parts.

- The original controller is upgraded, so don’t worry about not getting the 606W-TF controller.

- The ET-600 Upgrade version increases Pump_Over-biration’s fault tolerance and reduces machine maintenance time.